The Knowledge You Have to Know about Rapid Prototyping

2018-04-19

Rapid Prototyping (RP) can be defined as a group of techniques used to quickly fabricate a scale model of a part or assembly using three-dimensional computer aided design (CAD) data.

It has also been referred to as solid free-form manufacturing; computer automated manufacturing, and layered manufacturing. RP has obvious use as a vehicle for visualization. In addition, RP models can be used for testing, such as when an airfoil shape is put into a wind tunnel. RP models can be used to create male models for tooling, such as silicone rubber molds and investment casts. In some cases, the RP part can be the final part, but typically the RP material is not strong or accurate enough. When the RP material is suitable, highly convoluted shapes (including parts nested within parts) can be produced because of the nature of RP.

Rapid prototyping isn't a solution to every part fabrication problem. After all, CNC technology is economical, widely understood and available, offers wide material selection and excellent accuracy.

WHY RAPID PROTOTYPING?

• To increase effective communication.

• To decrease development time.

• To decrease costly mistakes.

• To minimize sustaining engineering changes.

• To extend product lifetime by adding necessary features and eliminating redundant features

• Rapid Prototyping decreases development time by allowing corrections to a product to be made early in the process. By giving engineering, manufacturing, marketing, and purchasing a look at the product early in the design process, mistakes can be corrected and changes can be made while they are still inexpensive.

• The trends in manufacturing industries continue to emphasize the following:

• Increasing number of variants of products. • Increasing product complexity.

• Decreasing product lifetime before obsolescence.

• Decreasing delivery time.

• Rapid Prototyping improves product development by enabling better communication in a concurrent engineering environment.

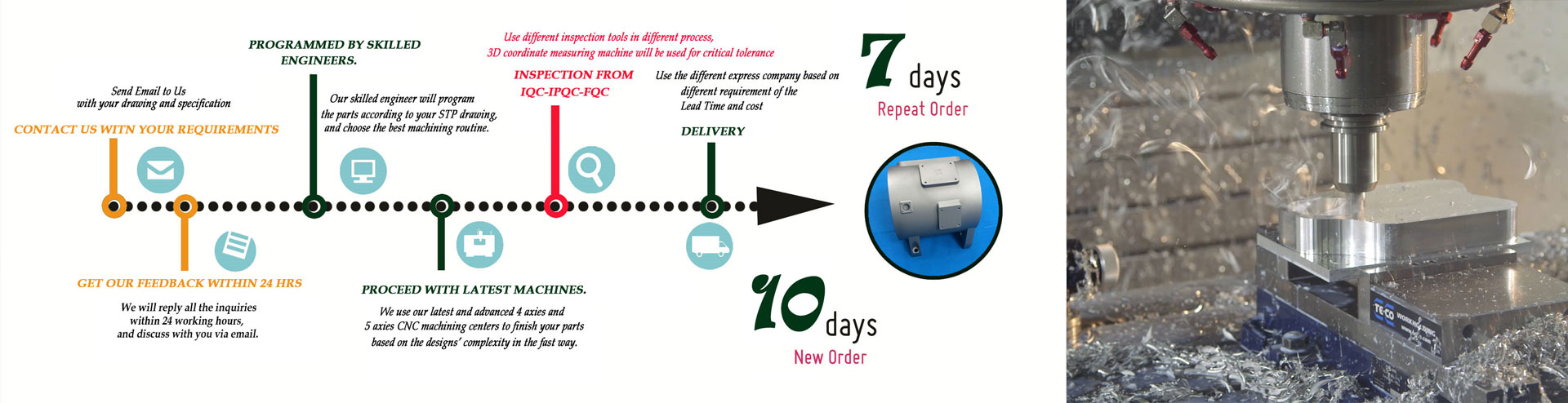

THE BASIC PROCESS

Although several rapid prototyping techniques exist, all employ the same basic five-step process. The steps are:

1. Create a CAD model of the design

2. Convert the CAD model to STL format or other 3D drawing such as STP, IGS and so on

3. Transfer the drawing into Printing files or programming according to the 3D drawings

4. Construct the model in different technic based on the requirements

5. Clean and finish the model

If you have any project need rapid prototyping, just contact our sales engineer at sales@precisetechnic.com