SLA & SLS Rapid Prototyping

2018-04-12

SLA & SLS Rapid Prototyping

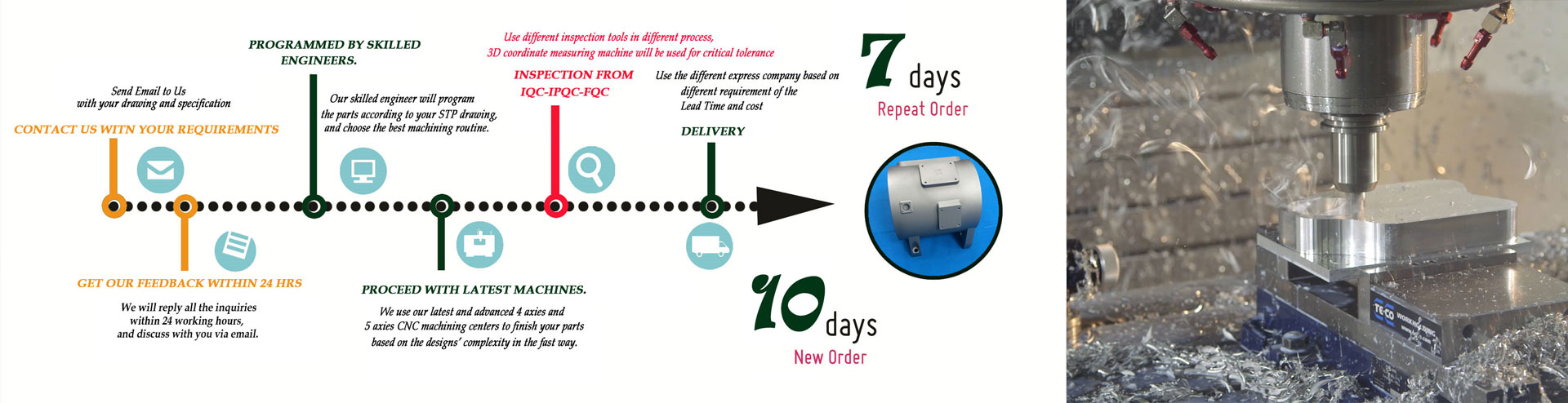

Rapid prototyping is a method of manufacturing parts in low volumes and can provide you with a fully detailed component within a short lead time. There are a variety of options available to suit your specific requirements.

Originally known as Additive Manufacturing the processes available have advanced over recent years and there are dedicated companies who offer a comprehensive Rapid Prototyping service. In addition to our own in-house options we feel it is important that you can come to us to assist you throughout the entire development process. To enhance our own supply chain we provide a range of options to meet your prototyping requirements as a fully managed service.

The outsourced prototyping techniques available are….

Steriolithography Apparatus (SLA)

SLA was the first rapid prototyping technology and is a method of prototyping solid objects made up of thin layers of an ultraviolet curable material. These layers are exposed to an ultraviolet laser light that cures and solidifies the pattern traced on the resin and joins it layer by layer. After the pattern has been traced the build platform drops by a variable distance depending on the accuracy of the machine running the application. A blade will then sweep across the part to re-coat it with fresh material and the process is repeated. After the parts are built they are immersed in a chemical bath to be cleaned of excess resin and are then cured in an ultraviolet oven.

Advantages:

· Speed

· Short lead time

· Functional parts

Disadvantages:

· Can be expensive

· No additional material options available

· Parts can be brittle

Selective Laser Sintering (SLS)

SLS prototypes are produced by melting and fusing particles together in layers. The process relies on a laser to melt a flame retardant plastic powder which then solidifies to form a layer. The sintering process is also compatible with building metal objects as the principles of melting and reshaping still apply.

The three dimensional parts are created by having layers of material fused together by a high power laser. The laser selectively fuses powdered material by scanning cross-sections generated from a 3D cad file and recreates it on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is complete.

The powder bed provides the necessary support for the parts negating the need for any additional support material. Once the part is complete it is raised from the powder bed and any excess powder can be brushed away, parts are usually built in either a glass filled or unfilled Nylon.

Advantages:

· Complex geometry

· Self-supported during build

· Durability and strength of finished parts

· No post curing

· Parts can be sanded and painted

Disadvantages:

· Parts can be porous

· Surface finish can be grainy

· Parts are weaker than machined or moulded components

At PT, we provide SLA and SLS rapid prototyping for your new design based on different function. Just get the free quotation from US within 24 hours working days.