Do you need Rapid Tooling for your parts?

2018-05-22

RAPID TOOLING

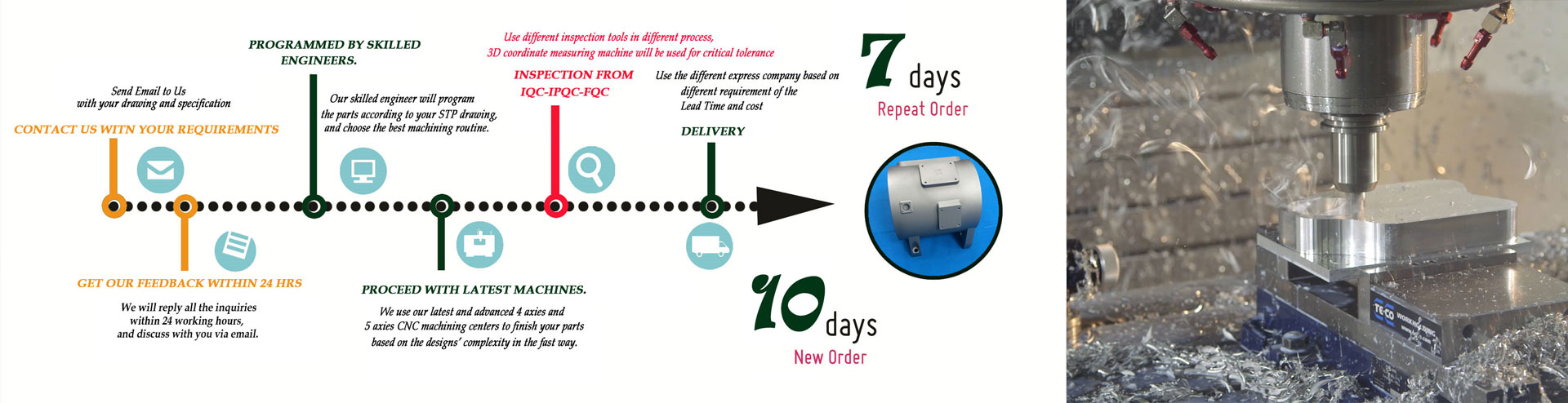

The term Rapid Tooling (RT) is typically used to describe a process which either uses a Rapid Prototyping (RP) model as a pattern to create a mold quickly or uses the Rapid Prototyping process directly to fabricate a tool for a limited volume of prototypes. RP techniques can also be used to make tooling (referred to as Rapid tooling) and even production quality parts (Rapid manufacturing).

For small production runs and complicated objects, rapid prototyping is often the best manufacturing process available. Of course, "rapid" is a relative term. Most prototypes require from three to seventy-two hours to build, depending on the size and complexity of the object. This may seem slow, but it is much faster than the weeks or months required to make a prototype by traditional means such as machining.

These dramatic time savings allow manufacturers to bring products to market faster and more cheaply. In 1994, Pratt & Whitney achieved "an order of magnitude [cost] reduction [and] . . . time savings of 70 to 90 percent" by incorporating rapid prototyping into their investment casting process.

RAPID TOOLING VS CONVENTIONAL TOOLING

-

Tooling time is much shorter than for a conventional tool. Typically, time to first articles is below one-fifth that of conventional tooling.

-

Tooling cost is much less than for a conventional tool. Cost can be below five percent of conventional tooling cost.

-

Tool life is considerably less than for a conventional tool.

-

Tolerances are wider than for a conventional tool.

IMPORTANCE OF RAPID TOOLING

-

Tooling is one of the slowest and most expensive steps in the manufacturing process, because of the extremely high quality required.

-

Tools often have complex geometries, yet must be dimensionally accurate to within a hundredth of a millimeter.

-

In addition, tools must be hard, wear resistant, and have very low surface roughness (about 0.5 micrometers root mean square).

-

To meet these requirements, molds and dies are traditionally made by CNC-machining, electro-discharge machining, or by hand.

-

All are expensive and time consuming, so manufacturers would like to incorporate rapid prototyping techniques to speed the process.

Most rapid tooling today is indirect. RP parts are used as patterns for making molds and dies. RP models can be indirectly used in a number of manufacturing processes.

| Vacuum Casting |

It is the simplest and oldest rapid tooling technique, a RP positive pattern is suspended in a vat of liquid silicone or room temperature vulcanizing (RTV) rubber. When the rubber hardens, it is cut into two halves and the RP pattern is removed. The resulting rubber mold can be used to cast up to 20polyurethane replicas of the original RP pattern. A more useful variant, known as the Keltool powder metal sintering process, uses the rubber molds to produce metal tools. Developed by 3M and now owned by 3D Systems, the Keltool process involves filling the rubber molds with powdered tool steel and epoxy binder. When the binder cures, the "green" metal tool is removed from the rubber mold and then sintered. At this stage the metal is only 70% dense, so it is infiltrated with copper to bring it close to its theoretical maximum density. The tools have fairly good accuracy, but their size is limited to under 25 centimeters. |

| Sand Casting | A RP model is used as the positive pattern around which the sand mold is built. |

| Investment Casting |

Some RP prototypes can be used as investment casting patterns. The pattern must not expand when heated, or it will crack the ceramic shell during autoclaving. Both Stratasys and Cubital make investment casting wax for their machines. |

| Injection molding | A manufacturing process for producing parts by injecting molten material into a mould. Injection moulding can be performed with a host of materials mainly including metals, (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (Using a helical shaped screw), and injected (Forced) into a mould cavity, where it cools and hardens to the configuration of the cavity. |